Silo Aeration Components

Grain growers and handlers use aeration for a range of quality-related reasons, including to:

- protect grain quality

- moisture management

- store damp grain longer

- reduce condensation and caking

- avoid 'hot spots'

- lower temperature and moisture levels

- preserve seed germination

- control insect activity

- prevent moulding and sprouting

- avoid chemical residues

Control of Insects

Controlled aeration lowers the temperature of the grain bulk during long-term storage, reducing insect activity dramatically. To satisfy certain market standards an additional step of fumigation in a sealable storage may be needed to ensure totally insect-free grain at delivery.

A combination of Aeration and Dryacide blanketing is also effective in protecting grain against insects without leaving chemical residues.

Silo sealing greatly assists in insect control but does not provide all benefits that effective aeration can provide. Aeration fans significantly speed up the removal of toxic gases post fumigation.

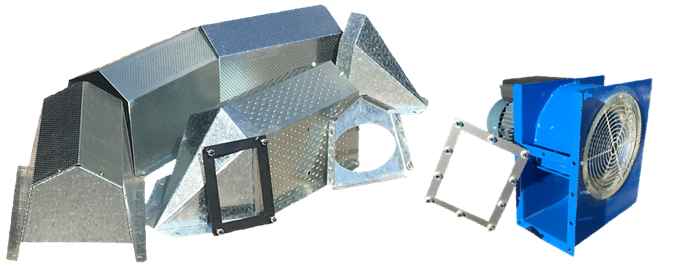

On-floor ducting

On-floor ducting

Equipment

Aeration systems include:

- various size fans depending on application

- perforated ducting to distribute air within the storage

- optional - automatic controllers to select the best fan operating times

Openings are needed at the top of storages to allow exhaust air out and prevent excessive back-pressure. This is especially important if aeration is used on sealed storages - a venting system must be provided on the roof.

Grain on the north west wall of storage heats most because a greater amount of sunshine falls on that area. Shading the storage, painting the external surfaces white or using Zincalume silos reduces the heat load and improves aeration performance.

Poorly-matched equipment reduces aeration performance. Buying your equipment from Customvac means you will get advice from experienced aeration experts who supply detailed operating instructions and back-up after the sale.

Elevated Cone Silos

Elevated Cone Silos

Fans to suit all applications

Fans to suit all applications

Automatic Control

Automatic aeration controllers take the guesswork out of silo aeration, particularly for long term storage of grain. They change their settings automatically to select the coolest available air and correct operating times.... high performance with less operator input. The cost of an automatic controller is outweighed by the lower risk of grain losses. One unit can control up to 24 storages. Automatic controllers add little to the initial cost per tonne of storage but quickly pay for themselves through better grain quality

Automatic Control

Automatic Control

Aeration for Silos

Aeration for Silos Aeration for Sheds

Aeration for Sheds