The Benchmark in waste and product transfer for the

Food Manufacture, Stock-feed and Milling Industries

Walinga Central Vac Systems continue to evolve, thriving in the most demanding of environments. Vac systems help eliminate facility's debris or residue from spills and minimize the health and explosive risks associated with dust. Install a system for production line product retrieval, reusing what may have once been considered of no value. Design a multi-floor, multi-drop system for larger installations. Walinga Central Vac Systems feature tried and proven components familiar to all Walinga transfer products. From steel mills to feed mills, Walinga Central Vac Systems provide low cost, task tailored, product recovery solutions. Committed to delivering the best solutions, Customvac technical representatives maintain a dialogue with new and old clients alike. Field tested client inspired innovations are always evaluated and many will make it to production.

How it Works

The Central-Vac system is powered by a Walinga Super Chrome Blower. The Blower provides suction throughout the system which may cover a number of Factory Floor levels. Pick up points are installed based on the customers design to ensure high need areas are covered. Dust laden air is drawn to a common point where the product is separated from the air through dual cyclone units. The collected material can readily be transferred for rework or scrapped as required.

Advantages

- Improved Plant Hygiene, less opportunity for cross contamination, reduced insect activity

- Cleaner Safer working conditions for staff

- Improved operator efficiency

- Reduced Dust Explosion Risk

- Reduced Manual Handling

The Components

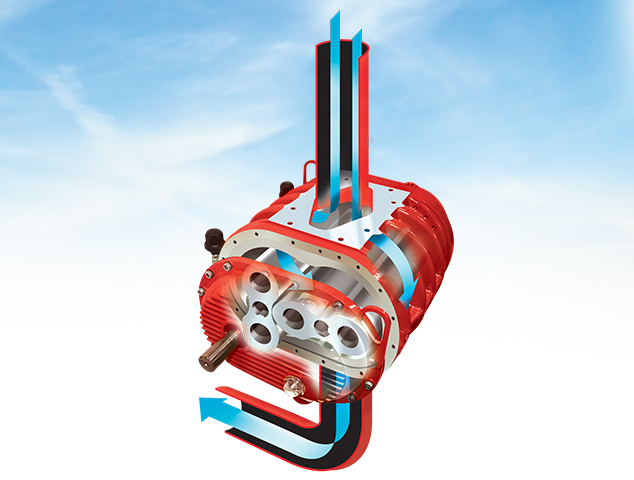

Blower

Walinga Super Hardened SRT Blowers are manufactured to exact specifications and quality control standards. The housing, end plates and impellers are precision machined.

Gears and bearings are "splash lubricated". For the Central Vac application, these blowers operate at very low rpms extending the life of the blowers.

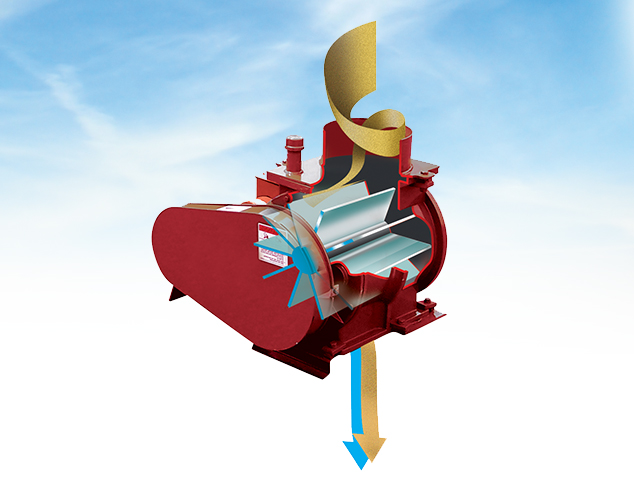

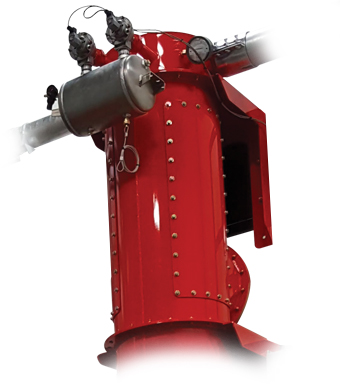

Primary Cyclone

Comprehensive engineering capabilities allow for the unique computer designed cyclone fitted to your specific application. Designed to provide optimum performance and to keep discharge dust to a minimum. The Separator provides effective separation of dirt and air. Combined with the separately controlled drop-thru airlock, the Separator contents can be discharged into dumpster or back into your production system. Primary Separator is available with a liner.

Air Lock

Cast iron precision machined housing for longer life. Adjustable tips available in Knife Edged Carbon Steel, Stainless Steel and Composite Rubber. Electric Motor for separate start/stop operation.

Optional: Super Hardened Airlock

Secondary Cyclone

Located “up-stream” of the blower, the Secondary Cyclone is designed to remove excess dust from the air stream prior to the air getting to the blower. The Secondary Cyclone is designed to remove additional dust not caught by the primary separator. This allows for minimal dust to reach the filter canister.

(SHOWN: Optional Automated Slide Gate)

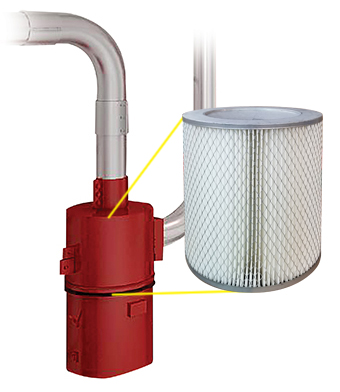

Filter Canister

The filter canister can be located in a easy to maintain location close to the ground. It keeps dust out of the blower, which protects and prolongs its life. It also ensures clean air discharge from the blower into the atmosphere.

New Air Purge System

This new Central-Vac System features Air Purge Self-Cleaning Technology. Four self-cleaning filters within an explosion-proof housing replace traditional filter canisters, filter cleaning, and replacement. Designed to National Fire Protection Association standards, Air Purge technology reduces explosive risks, maintenance time and costs while promoting a cleaner, healthy work environment.

Super-hardened blower with SRT

Super-hardened blower with SRT Primary Cyclone with Drop Thru Airlock

Primary Cyclone with Drop Thru Airlock  Drop thru airlock with adjustable tips

Drop thru airlock with adjustable tips  Secondary cyclone with optional automated slide

Secondary cyclone with optional automated slide  Cannister filter to remove fines before discharge

Cannister filter to remove fines before discharge New Air Purge Cyclone system

New Air Purge Cyclone system